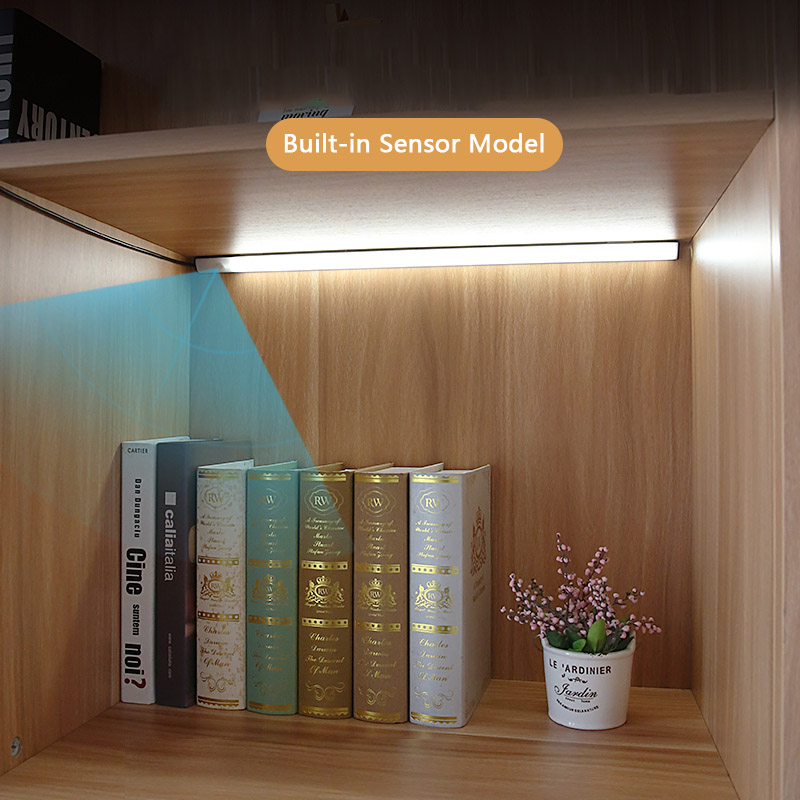

Aluminum profile LED strip light has been used in many furnitures like cabinets, closets, for there is a wide range of aluminum channel shapes, flexible tailored length of light strips, optional color temperatures, meeting different decoration demands to enhance the overall aesthetic appeal. Though this type of LED strip light is widely used, there are problems coming after. The typical one is hard to maintain since the light strip is welded with the electriciy cable, which potentially increase the replacement cost if the light strip is demaged. Those recessed-in installed light is even harder to change for it is recessed into the panels of cabinet or other furnitures.

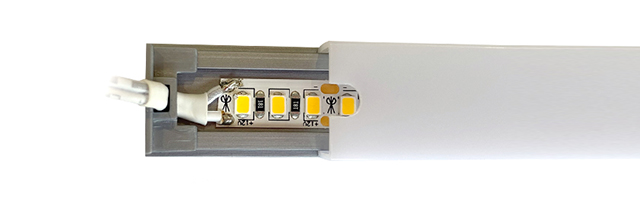

“Plug-and-Play” LED Strip Light

New welded free aluminum LED light strip is designed to solve the issue by separated the light strip and cable. Unlike the traditional aluminum channel light strip , this new type of light strip is not welded with the cable, instead the cable is welded with the end cap, creating a new “plug in and play design”, you simply put the light strip onto aluminum channel and put on the end cap (with cable). This design has dramatically save the efforts for maintainance since it omits the steps of welding. It may also save your budget since it is easy to install.

Benefits of Using Solderless LED Strip Light

1.Time and Effort Saving

It is the original intention of this design — time and effort saving maintainance. It eliminates the need for traditional welding, significantly reducing both the complexity and time required for installation.

Solderless LED strip lights can reduce installation time by Max. 50% compared to time of traditional soldered LED strips installation. For instance, a professional lighting installation firm reported that it cut their average cabinet lighting setup time from 4 hours down to 2 hours per project after switching to solderless strip lights.

2.Cost Saving

The light strip uses plug-and-play connectors, allowing for quick and easy joining, extension of LED strip lights, making the installation process accessible even to non-professionals. For example, a homeowner who wants to add lighting under kitchen cabinet can simply snap the connectors together without any technical skills and tools. The user-friendly design not only simplifies the setup but also enables easy adjustments or expansions in the future, making it ideal for regular users.

3.Flexibility of No-Solder LED Strip

Solderless LED strip light allows users to detach and reconfigure the strips based on their changing needs. Its modular design makes it simple to make adjustable change of light strip length or control switch.

For example, lighting arrangement often needs to be modified as to highlight new products or store promotions activities in retail store. With the flexibility of solderless LED strip light, the store staffs can reset or extend the light strip even though they are not professionals technicians.

Will the connector get loosen over time?

Consumers may be skepical about the reliability of No-solder LED strip: Will the connector get loosen over time or even demages the light strip. A well-designed connectors ensure reliable electrical contact and stable connections, preventing loosening or disconnection over time. Take a commercial display lighting where consistent illumination is critical as an example, these secure connectors maintain uninterrupted power flow even in environments subject to vibration or movement.

Regular Models of Welding-free LED Light Strip

There are hundreds of different types of LED light strip availale in the market due to various demands. Here are some most used light strips.

1.Recessed-in LED light strip with 10*10mm Aluminum Channel

This model must be the most popular solderless light strip because its aluminum channel is only H10*W10mm, which requires not much efforts to dip a slot for installation, but keep the light strip invisible from the cabinets or other furnitures. (Our LED light strip 31122 is this type of light strip.)

2.Surface Mounted LED Light Strip with Slim Aluminum Channel

Compared to recessed-in LED light strip, surface mounted model is more time-saving for installation and maintainance. It is more popular if the model is with slim aluminum channels since it is nearly invisible and don’t affect the aesthetics of the furniture.

3.Triangle Aluminum Channel LED Light Strip

This type of light strip comes with a specially designed triangle channel, whose size is usually W10mm*H10mm. This light strip is installed onto the corner of a shelf (As the picture shown), which make full use of a cabinet, providing ambinet lighting and take up no space.

4.45°Lighting Angle LED Light Strip

This type of light strip features an asymmetric light channel, a blade-like edge on one side, creates a 45° lighting angle. This feature bring a focused and glare-free illumination for accent or task lighting on the cabinet. It is commonly applied on display cabinets.

5.Stick-on Board LED Light Strip

Stick-on board Light Strip is frequently seen on float shelf or wine cabinet. The typical feature of this light strip is that it is sticked to the edge of cabinet board, provide lighting for up and down.

Welding free LED light strip has been a big trends for furniture lighting. Compared to traditional lighting fixtures, these light strip is more flexible , with customized length or various end cap switch for meeting various furniture lighting demands.