The Importance of LED Driver

As we introduced before, LED driver is an electronic device that regulates the power supply to an LED lighting system. It converts the incoming alternating current (AC) power to direct current (DC) power, while also controlling the current and voltage supplied to the LED lights. This functionality directly impacts the performance, efficiency, and durability of the LED lights.

How LED Driver Manufacturer Control the Quality ?

It is important to know the process of how manufacturer control the quality since it ensures you are having high quality LED driver for lighting system or for your business if you are in LED industry.

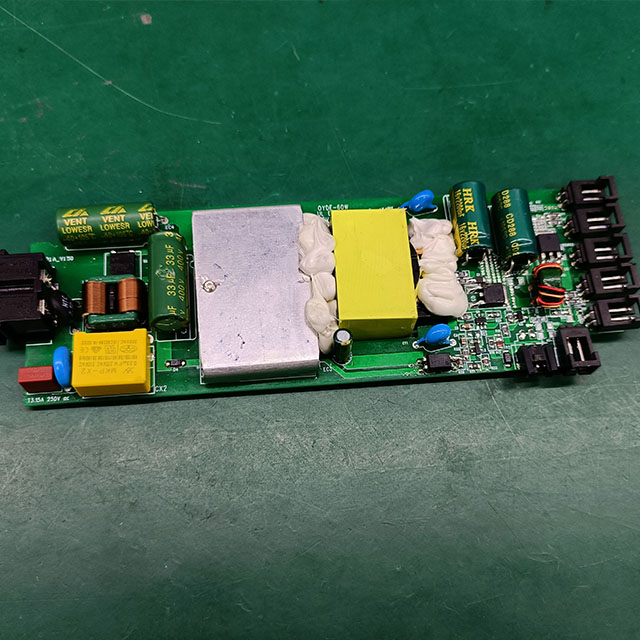

1.Selecting high quality components and conducting strict inspection

Like other manufacturing industries, using high quality components and parts contribute to high quality end products. LED driver is no exception. For example, we are only purchase LED driver components and parts from reliable suppliers that we are cooperating and conduct strictive in-coming raw materials inspection under standard procedure. Those components fail to meet the criterias will be rejected to the production process.

2.Design Validation

Before moving into the manufacturing phase, LED driver designs are subjected to thorough validation processes. This involves simulations and prototypes to test the performance under different conditions. Any flaws or inefficiencies are identified and rectified at this stage to prevent issues from arising during mass production.

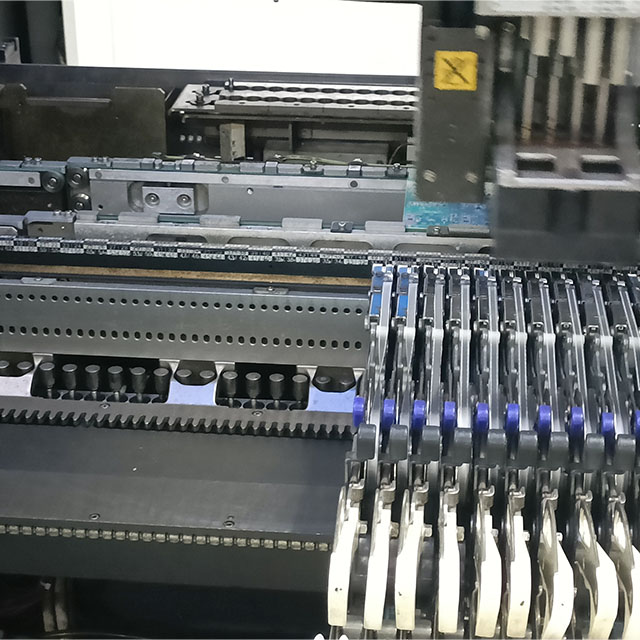

3.Manufacturing Process Control

LED driver manufacturer implements stringent manufacturing processes to maintain consistency and reliability. Automated assembly lines, precision soldering, and advanced machinery are employed to minimize human error and ensure consistent product quality.

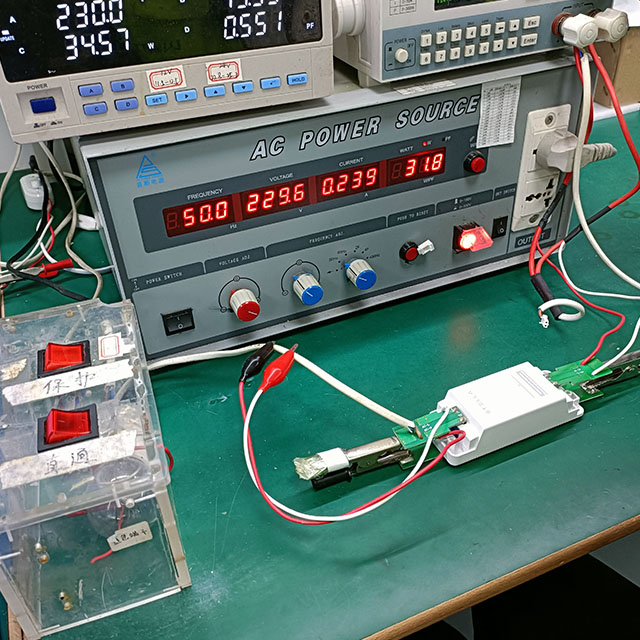

4.Quality Assurance Testing

Besides the in-coming raw materials inspection and Manufacturing process control, LED driver needs to undergo a series of exhaustive tests to verify their performance, efficiency, and safety. These tests include thermal cycling, voltage regulation assessments, and electromagnetic interference (EMI) testing. Products that fail to meet the predefined criteria are rejected and reture to manufacturing process.

5.Burn-in and Reliability Testing

To simulate real-world conditions, LED drivers often undergo burn-in tests where they are operated under stress conditions for an extended period. This helps identify any potential defects that might emerge over time and ensures the longevity of the product.

6.Certifications and Compliance

Reputable LED driver manufacturers seek third-party certifications and compliance approvals from relevant industry standards organizations. This further validates the quality and safety of their products, assuring customers that the LED drivers meet international standards.

7.Continuous Improvement

The pursuit of excellence is an ongoing process. LED driver manufacturers regularly analyze feedback from the field, gather data on product performance, and implement necessary improvements. This commitment to continuous improvement ensures that their LED drivers evolve with the ever-changing technology landscape.